宜兴市国安减速传动设备有限公司

Yixing Guo'an Reducer Transmission Equipment Co., Ltd.

宜兴市国安减速传动设备有限公司

Yixing Guo'an Reducer Transmission Equipment Co., Ltd.

PRODUCTS

Guo'an Reducer Transmission Equipment

PRODUCTS

Top entry mixer

1. JBG series high speed mixer

(1) Overview of JBG series high-speed mixer

This model adopts motor, pulley, cycloidal pinwheel or helical gear reducer as the power to design and manufacture, the structure is simple, compact and beautiful. This model can be directly used in normal pressure mixing operations, and can also be used with a rack for pressure vessel mixing where mechanical seals need to be installed.

According to different stirring purposes, different forms of agitator impellers, such as FY, CL, ZHX, FY, MK, YK, TXL, etc., are configured. The materials can be divided into carbon steel, stainless steel, rubber-lined and engineering plastics, etc. It can be used for liquid mixing, dissolution, solid suspension, heat transfer, reaction, decomposition, crushing and dosing and stirring in the environmental protection industry.

(2) Model representation

JBG (V) 300/FY—1000—Y5.5—S1

Stirrer material code

Motor code (Y, YB explosion-proof, YVP frequency conversion, GMBL speed regulation, etc.)

mixer revolutions per minute

Stirrer Diameter/Form

Belt drive (not marked as reducer drive)

Top entry high speed mixer for short

(3) Product drawing

.jpg) |

.jpg) |

.jpg) |

| Gear Driven High Speed Mixer | Motor drive high speed mixer | Gear belt toothed turbine high speed mixer |

.jpg) |

.jpg) |

.jpg) |

| Gear belt rack high speed mixer | Pulley drive high speed mixer | Cycloidal drive high-speed mixer |

(4) Selection and main parameters of JBY series movable mixer

.jpg)

| Model | Power | Rotating speed | Impeller | Spindle | Main dimensions | |||

| JBG | KW | r/min | ØD | Ød | L1 | L2 | L3 | D1 |

| 1 | 0.09 | 100-1000 | 50-100 | 10-16 | ~120 | ﹤800 | ﹤300 | |

| 2 | 0.12 | 100-1000 | 50-100 | 10-16 | ~120 | ﹤800 | ﹤300 | |

| 3 | 0.18 | 100-1000 | 100-150 | 10-20 | ~250 | ﹤800 | ﹤300 | |

| 4 | 0.25 | 100-1000 | 150-180 | 16-20 | ~250 | ﹤800 | ﹤300 | |

| 5 | 0.37 | 80-800 | 150-250 | 20-25 | ~280 | ﹤1000 | ﹤400 | |

| 6 | 0.55 | 80-800 | 180-300 | 20-25 | ~280 | ﹤1200 | ﹤400 | |

| 7 | 0.75 | 80-600 | 250-400 | 30 | ~340 | ﹤1400 | ﹤400 | |

| 8 | 1.1 | 80-500 | 300-450 | 35 | ~550 | ﹤1800 | ﹤500 | |

| 9 | 1.5 | 80-500 | 300-550 | 35 | ~550 | ﹤1800 | ﹤500 | |

| 10 | 2.2 | 80-300 | 400-700 | 40 | ~650 | ﹤2500 | ﹤600 | |

| 11 | 3 | 80-300 | 400-750 | 50 | ~650 | ﹤2500 | ﹤600 | |

(5) Selection and main parameters of JBG series high-speed toothed disc turbine mixer

.jpg)

.jpg)

Due to the above operating characteristics of this series of mixers, the motor power consumption is relatively large under the condition of ensuring stable operation, and the working efficiency of the reducer and motor is very high. Please consult our company for selection.

(6) JBGV pulley drive high-speed mixer

JBGV pulley drive high-speed mixer is a new type of belt drive mixer designed according to foreign products. The transmission belt adopts high-strength and narrow V-belt, which has a 50% higher bearing capacity than ordinary V-belt. It has long life, compact structure, stable transmission, disassembly and assembly. Convenience and so on.

JBGV pulley drive high-speed mixer can be divided into two types: low-power series and high-power series. The low-power series motor is combined with the reduction frame, and the stirring shaft is generally directly connected to the stirring shaft by using a jacket coupling and an empty sleeve type. The high-power series motor and reduction frame are installed on a vertical independent platform; and the stirring shaft generally adopts a jacket coupling and a cylindrical type that is directly connected to the stirring shaft in the kettle body. Generally, there is no coupling or center of gravity outside the kettle. Easy to replace and adjust mechanical seal. JBGV pulley drive high-speed mixer is widely used in food, pharmaceutical, tap water, large-scale biological fermentation system and environmental protection water treatment system with high environmental hygiene standards.

| Type | Drive mode | Equipped with power (kw) | Stirring speed (r/min) | Sealed form |

| JBGV low power type | Narrow V-belt drive | 0.37-22 | 180-600 | Stuffing box, machine seal |

| JBGV high power type | 5V narrow V-belt drive | 5.5-600 | 180-380 | Stuffing box, machine seal |

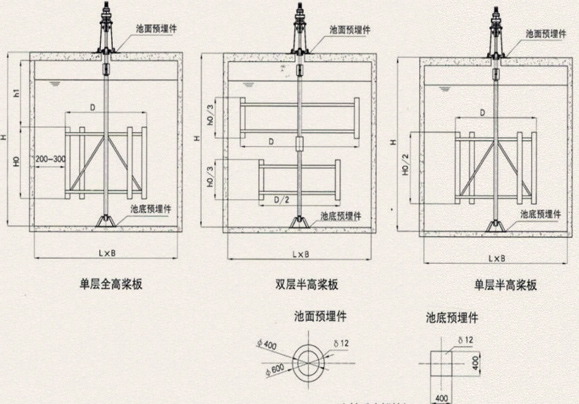

(7) Installation of JBG series high-speed mixer in environmental protection water treatment industry

.jpg)

Instruction:

1. Indicate the length, width and height (or diameter and depth) of the cell body.

2. Indicate the material of the underwater parts.

3. If it is an open pool body that needs to work bridge, it is necessary to verify the size of the embedded steel plate.

4. Please contact our company for specific selection.

2. JBZ series medium speed mixer

(1) Overview of JBZ series medium speed mixer

This model adopts cycloidal pinwheel or helical gear reducer as power design and manufacture, and has the characteristics of simple structure, compactness, smooth transmission, low noise, high efficiency, high bearing capacity and good combination performance. This model is suitable for medium-load and heavy-duty mixing operations, and is often equipped with a rack for mixing occasions of large and medium-sized pressure vessels that require mechanical seals.

According to different stirring purposes, different forms of agitator impellers, such as XJ, ZJ, HY, PK, YCK, LD, KS, TS, etc., are configured. The materials can be divided into carbon steel, stainless steel, rubber-lined and engineering plastics, etc. Low and medium viscosity liquid mixing, dissolving, solid suspension, heat transfer, reaction, extraction, crystallization and chemical mixing in environmental protection industry, rapid mixing and reaction of raw water and coagulant, etc.

(2) Model representation

JBZ 700/ZJ—80—Y2.2—S1

Stirrer material code

Motor code (Y, YB explosion-proof, YVP frequency conversion, GMBL speed regulation, etc.)

mixer revolutions per minute

Stirrer Diameter/Form

Top entry medium speed mixer for short

(3) Product drawing

.jpg) |

.jpg) |

.jpg) |

| Cycloidal drive belt rack medium speed mixer | Cycloidal Drive Folding Type Medium Speed Mixer | Gear Drive Ribbon Medium Speed Mixer |

.jpg) |

.jpg) |

.jpg) |

| Geared Belt Rack Medium Speed Mixer | Geared Medium Speed Mixer | Gear Drive Folding Slurry Medium Speed Mixer |

.jpg)

(4) Selection and main parameters of JBZ series medium speed mixer

| Model | Power | Rotating speed | Impeller | Spindle | Main dimensions | |||

| JBZ | KW | r/min | ØD | Ød | A | B | L | I |

| 1 | 1.1 | 20-100 | 400-500 | 32-38 | ~150 | ~450 | ﹤1800 | |

| 2 | 1.5 | 20-100 | 400-600 | 38 | ~150 | ~450 | ﹤1800 | |

| 3 | 2.2 | 20-100 | 600-700 | 45-57 | ~200 | ~500 | ﹤2500 | |

| 4 | 3 | 20-100 | 600-800 | 57 | ~200 | ~500 | ﹤2500 | |

| 5 | 4 | 20-80 | 700-1000 | 57-76 | ~220 | ~700 | ﹤2800 | |

| 6 | 5.5 | 20-80 | 800-1000 | 76 | ~280 | ~700 | ﹤2800 | |

| 7 | 7.5 | 20-80 | 1000-1200 | 76-89 | ~280 | ~800 | ﹤3000 | |

| 8 | 11 | 20-80 | 1200-1500 | 89-108 | ~450 | ~1200 | ﹤3500 | |

| 9 | 15 | 20-80 | 1500-2000 | 108-133 | ~500 | ~1200 | ﹤3500 | |

(5) Installation of JBZ series medium speed mixer in environmental protection water treatment industry

.jpg)

Instruction:

1. Indicate the length, width and height (or diameter and depth) of the cell body.

2. Indicate the material of the underwater parts.

3. If it is an open pool body that needs to work bridge, it is necessary to verify the size of the embedded steel plate.

4. Please contact our company for specific selection.

3. JBM series low speed mixer

(1) Overview of JBM series low-speed mixer

This model adopts two-stage or multi-stage cycloidal pinwheel, helical gear reducer, arc gear worm gear reducer, hydraulic, etc. as the power design and manufacture. It has compact structure, large transmission ratio, stable operation, low noise and high efficiency. High, high bearing capacity, good combination performance, low cost and so on. This model is suitable for heavy-duty mixing operations.

According to different stirring purposes, different forms of agitator impellers, such as EJ, SJ, BJ, LG, ZLG, BKS, FKS, FSS, etc., are configured. The materials can be divided into carbon steel, stainless steel, rubber-lined and engineering plastics, etc. Medium and high viscosity liquid mixing, dissolving, solid suspension, heat transfer, reaction, crystallization and flocculation, multi-stage reaction, mud scraper, mechanically accelerated clarifier stirring and mud scraping in the environmental protection industry.

(2) Model representation

JBM 1600/FKS—5—Y2.2—S1

Stirrer material code

Motor code (Y, YB explosion-proof, YVP frequency conversion, GMBL speed regulation, etc.)

mixer revolutions per minute

Stirrer Diameter/Form

Top entry low speed mixer for short

(3) Product drawing

.jpg) |

.jpg) |

.jpg) |

| Worm Drive Mud Mixer | Cycloidal drive frame mixer | Cycloid center drive mud scraper |

.jpg) |

.jpg) |

.jpg) |

| Cycloidal Drive Double Ribbon Mixer | Slewing bearing center drive mud scraper | Mechanically Accelerated Clarifier Mixing Sludge Scraper |

(4) Selection and main parameters of JBM series low-speed frame-type reaction mixer

| Model | Stirring frame blade size (mm) | Power (kw) | Speed (r/min) | ||||||

| JBM | H | D | H0 | I | II | III | I | II | III |

| 1 | 1500 | 500 | 700 | 0.55 | 0.37 | 0.25 | 10 | 8 | 5 |

| 2 | 1800 | 600 | 1000 | 0.75 | 0.55 | 0.37 | 10 | 8 | 5 |

| 3 | 2000 | 700 | 1200 | 0.75 | 0.55 | 0.37 | 10 | 8 | 5 |

| 4 | 2300 | 800 | 1200 | 1.1 | 0.75 | 0.55 | 10 | 8 | 5 |

| 5 | 2500 | 1000 | 1500 | 1.1 | 0.75 | 0.55 | 10 | 8 | 5 |

| 6 | 2800 | 1200 | 1500 | 1.5 | 1.1 | 0.75 | 8 | 5 | 3 |

| 7 | 3200 | 1500 | 1800 | 1.5 | 1.1 | 0.75 | 8 | 5 | 3 |

| 8 | 3500 | 1800 | 2000 | 1.5 | 1.1 | 0.75 | 8 | 5 | 3 |

| 9 | 4300 | 2500 | 2500 | 2.2 | 1.5 | 1.1 | 5 | 3 | 2 |

| 10 | 4800 | 3000 | 3000 | 3 | 2.2 | 1.5 | 5 | 3 | 2 |

Instruction:

1. Indicate the length, width and height (or diameter and depth) of the cell body.

2. Indicate the material of the underwater parts.

3. If it is an open pool body that needs to work bridge, it is necessary to verify the size of the embedded steel plate.

4. If there are special requirements for the frame and leaf level or speed of the mixer, it should be indicated.

5. Please contact our company for specific selection.

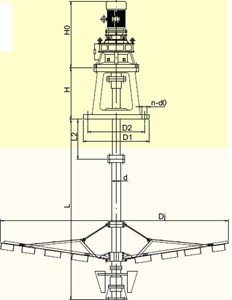

(5) Selection and main parameters of JBM series low-speed cycloid drive center drive mud scraper

| Model | Power | Rotating speed | Installation size | Torque | ||||||||

| JBM | KW | r/min | d | D1 | D2 | L2 | n-d0 | L | Dj | H | H0 | N.m |

| 410 | 0.37 | 0.32 | 80 | 460 | 420 | 300 | 12-Ø 18 | by actual design size custom made |

500 | 720 | 1800 | |

| 421 | 0.55 | 0.26 | 90 | 495 | 455 | 300 | 12-Ø 18 | 540 | 870 | 2400 | ||

| 531 | 0.75 | 0.11 | 100 | 555 | 510 | 350 | 12-Ø 22 | 580 | 960 | 8300 | ||

| 631 | 1.1 | 0.12 | 125 | 600 | 560 | 400 | 16-Ø 22 | 580 | 1090 | 11000 | ||

| 741 | 1.5 | 0.085 | 140 | 700 | 650 | 400 | 16-Ø 27 | 650 | 1250 | 22000 | ||

| 842 | 2.2 | 0.076 | 160 | 700 | 650 | 500 | 16-Ø 27 | 750 | 1500 | 30000 | ||

| 853 | 3 | 0.06 | 180 | 880 | 810 | 500 | 20-Ø 27 | 900 | 2050 | 49000 | ||

instruction:

1. Indicate the length, width and height (or diameter and depth) of the cell body.

2. Indicate the material of the underwater parts.

3. If the tank body needs to work bridge, it is necessary to verify the size of the embedded steel plate.

4. Please contact our company for specific selection.

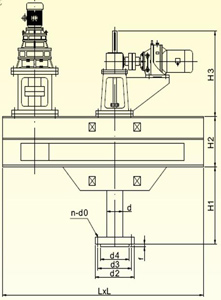

(6) Selection and main parameters of JBM series slewing bearing center drive mud scraper

| Model | Power | Installation size | Torque | |||||||||

| JBM | KW | d | H1 | H2 | H3 | d2 | d3 | d4 | n-d0 | f | L | N.m |

| 1 | 0.75-1.5 | 140 | 200+2S | 270 | 250+2S | 350 | 400 | 450 | 12-Ø 18 | 6 | 1100 | 1800 |

| 2 | 1.5-3 | 170 | 250+2S | 300 | 300+2S | 410 | 470 | 550 | 12-Ø 18 | 8 | 1540 | 3000 |

| 3 | 2.2-5.5 | 200 | 270+2S | 320 | 270+2S | 410 | 470 | 550 | 12-Ø 22 | 8 | 1940 | 45000 |

| 4 | 3-7.5 | 200 | 300+2S | 350 | 300+2S | 410 | 470 | 550 | 16-Ø 22 | 8 | 2540 | 6000 |

Instruction:

1. S represents the lifting height of the lift

2. Indicate the length, width and height (or diameter and depth) of the cell body.

3. Indicate the material of the underwater parts.

4. If the tank body needs to work bridge, it is necessary to verify the size of the embedded steel plate.

5. Please contact our company for specific selection.

HOME | ABOUT US | PRODUCTS | TECHNOLOGY | DOWMLOAD | NEWS | ORDER | CONTACT | 中文版

Copyright(C) 2009-2022, Yixing Guo'an Reducer Transmission Equipment Co., Ltd. All Rights Reserved. Supported by Toocle Copyright Notice 备案序号:苏ICP备10047348号